Knowledge

Application plan of roofing waterproof

Ⅰ. Project overview

Omit

Ⅱ. Application structure

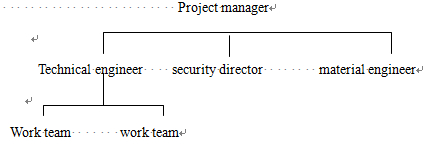

1. Structure charts

2. Make an application plan: prepare a working schedule, choose the experienced workers and a proper spray time.

3. Principle of choosing the materials: check with the product labels to ensure the proper qualified materials.

4. Training: the applicators should be familiar with the surface treatment, material storage, application technology process, inspection after spray and writing application report.

5. Conduct the tests to guarantee the application quality: test of the temperature, pre-spray to check the results, pressure control, check the flow rate and adhesive strength.

Ⅲ. Application preparation

1. Materials

Sealing primer: Epoxy primer,

Putty: spray polyurea elastomer material: polyurea waterproof coating

Polyaspartic polyurea UV topocat

2. Equipment

Spray equipment: special polyurea spray machine

Other auxiliary tools: air compressor, dryer, pneumatic stirrer, air purifier, steel wheels, waterproof cloth, cloth, anti fouling tapes.

3. Applicators

1-2 person to spray the gun, 2-4 auxiliary workers. They should have long term application experience and be professional trained.

4. Labor protection tools

Active carbon anti-dust respirators, goggles, gloves, safety belt etc.

5. Technology

(1) spray pressure

If the spray pressure is high, the atomization effect will be better. But need to make further protection of non spray area and the applicators.

(2) spray temperature

The temperature of material A & B should be heated to above 65 Celsius degree.

(3) air pressure and purifier

The air pressure should be above 8kg/cm2 and it requires to go through purifier and dryer to ensure the air is clean and dry, otherwise it will affect the quality even make surface bubbles or pinholes.

Ⅳ. Application process

1. Surface preparation of metal substrate.

Sand blasting the metal surface to Sa2.5 of ISO8501-1 or GB8923 standard.

(1) The standard that concrete substrate should be reached.

A, the concrete strength is not less than the strength requirements of structure design.

B, the surface is even with no defects, no sand, shells, cracks, voids and pits, check the smoothness with 2mm ruler, with space not bigger than 2mm.

C, Where the pipeline,casing, reserved holes, embedded parts through the substrate should be pre-embedding or set up.

D, in normal conditions, it requires the water content of concrete less than 3-4%, water vapor transmission rate less than 1.56kg/(100m2·24h)

(2) concrete base grinding and clean up

A, Remove the surface from oil, laitance, loose dust or releasing agent with polishing machine or wire brush.

B, Grind the surface even and make sure it is solid, compact, clean and even prior to apply primer.

(3) Apply primer.

(4) apply sealing putties

Apply two layer of putties after the concrete grinding even, to make sure the polyurea coating won’t have pinholes and bubbles. Apply the putties as the manufacturer’s instructions, control each layer thickness at 0.2-0.3mm, the interval time is 24h. If the thickness above 0.5mm it will cure slow and have bubbles. Make sure the surface doesn’t have pinholes, apply the following coatings in 24 hours after putty application.

2. Recommended matching plan of anticorrosion waterproof coatings

|

No |

Name of product |

Layer |

DFT(μm) |

Material coverage(kg/m2) |

|

1 |

Sealing puty |

1 |

400 |

0.3 |

|

2 |

Primer (2 layers) (HP6303K) |

2 |

100 |

0.3 |

|

3 |

Spray polyurea (PS500A) |

1 |

1500 |

1.8 |

|

4 |

Roll polyaspartic polyurea topcoat |

1 |

150 |

0.35 |

|

Total |

|

5 |

2150 |

2.75 |

3. Application procedures

Surface preparation (qualified) →brush two component primer 1 layer (after surface dry) →putty→ brush anther primer → spray polyurea 1 layer → roll the polyaspartic polyurea UV topcoat 1layer → acceptance

4. Spray polyurea

(1) Preparation before spray

A. Equipment and materials are placed in order.

B. Power supply at site: three-phase four wire (380V), 27KW, electric current 60A.

C. The pressure of air compressor: the pressure of air purifier and dryers should have 7-9kg.

D. Agitate part A & B uniform prior to application, especially part B shall be mixed thoroughly since it has inorganic fillers deposited. Insert the pneumatic agitator into the 3rd hole of part B, keep mixing during spray.

E. Spray machine: set the pressure 2500/3200psi, system temperature 60℃-75℃, the temperature of raw materials should be above 20℃. Start to spray polyuera after all sets in normal condition.

(2) technical requirements during spray process

A. The professional applicator starts to spray polyurea. Firstly, thoroughly spray a thin layer in the whole surface (commonly say priming), after that spray the required thickness 1.0mm±0.2 mm. During the spray process, in order to make the surface uniform, always make the second layer cover 50% of the previous layer.

B. The extra thicker treatment is needed in the junction, corner and connection joint places, spray 1.5-2.5mm thickness.

C. The coating surface should be even, without bubbles or peel off.

D. Once the coating is bonded with the shelter, the right method is to cut it by paper knife, do not pull it by force in case of any damages on the coatings.

E. Make the surface as beautiful as possible after properties guaranteed.

F. Blasting the surface where needs to repair, the blasting edge need to be extended 150mm away from the repair area. The fixing coatings have to be smooth transition from the around original coating.

5. Technical requirements during polyaspartic polyurea UV topcoat process

A. Strictly mix according to the provided ratio and stir well.

B. Construction thickness 150um

C. Scrape or roll topcoat construction

Ⅴ. Safety protection

1. Be familiar with the maintenance rules, safety handling regulations and methods.

2. Educate the applicators for the safety tips, such as fasten the safety belt and safety net.

3. Keep ventilation when apply indoor or sealed containers, the applicators shall wear goggles and anti-dust masks and wear protective clothes.

4. Be careful when making the mechanic polishing.

5. Use electric power safely.

CATEGORIES

KNOWLEDGE

CONTACT US

Name: Lily Lu

Mobile:86-13922763266

Tel:86-20-38993165

Whatsapp:8613922763266

Email:lilylu@huisins.com

Add:Room 206,Building 21,LongTeng Xing Cheng,No.68 LongTeng South Road, DongXiao Town, XinLuo District,LongYan City,FuJian Province.China