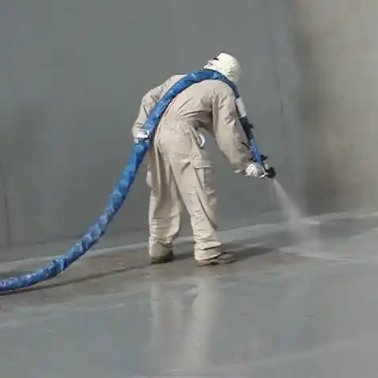

Power Plant Demineralized Water Tanks Spray Polyurea Coating

- Product Item : HS800G

- Category: Spray Polyurea Coatings

- HS800G is a breakthrough of the traditional anti-corrosion protection concept and integrated new materials,new technology and new process together.with excellent comprehensive physical properties and anti-corrosion performance .it has been successfully used in the power industry under various complicated corrosion environment.

HS800G is a high-performance, 100% solid content aromatic polyurea elastomer specifically formulated for the protection of power plant water storage equipment. It delivers robust, seamless protection for demineralized water tanks, offering superior adhesion and resistance to corrosion, water penetration, and moisture ingress. This product is widely applied in both domestic and international projects to ensure long-term integrity and safety of critical water storage infrastructure.

2.Features:● Without any thinner, environmental protection;

● Elongation, high flexibility, can adapt to the basic cracks and slight deformation;

● Good aging resistance

● Fast curing, can be sprayed on any surface, slope, vertical surface;

● Convenient construction, spraying a film.

3.Performance:

Item

Part A

Part B

Appearance

Pale yellow liquid

Adjustable color

Specific gravity

1.12

1.05

Viscosity(cps)@25℃

790

640

Solid content (%)

100

100

Mix ratio(by volume)

1

1

Gel time(second)@25℃

4-6

Tack-Free Time(second)

15-40

Theoretical Coverage(dft)

1.08kg/㎡ Film thickness 1mm

Physical properties

|

Item |

Test standard |

Result |

|

Hardness (Shore A) |

ASTM D-2240 |

90 |

|

Elongation at Break(%) |

ASTM D-412 |

460 |

|

Tensile strength(Mpa) |

ASTM D-412 |

17 |

|

Tear strength (kN/m) |

ASTM D-624 |

63 |

|

Impermeability(0.3Mpa/30min) |

HG/T 3831-2006 |

Impermeable |

|

Wearable(750g/500r)/mg |

HG/T 3831-2006 |

4.4 |

|

Adhesive strength(Mpa)concrete base |

HG/T 3831-2006 |

3.1 |

|

Adhesive strength(Mpa) steel base |

HG/T 3831-2006 |

11 |

|

Density(g/cm³) |

GB/T 6750-2007 |

1.02 |

|

Cathodic disbondment [1.5v,(65±5)℃,48h] |

HG/T 3831-2006 |

≤15mm |

Chemical resistance

|

Acid resistance 10%H₂SO₄ or 10%HCI,30d |

No rust, no bubbles, no peel off |

|

Alkali resistance 10% NaOH, 30d |

No rust, no bubbles, no peel off |

|

Salt resistance 30g/L,30d |

No rust, no bubbles, no peel off |

|

Salt spray resistance, 2000h |

No rust, no bubbles, no peel off |

|

Oil resistance 0# diesel, crude, 30d |

No rust, no bubbles, no peel off |

|

(For reference: the above data is acquired based on GB / T9274-1988 test standard. Pay attention to the influence of ventilation, splash and spillage. Independent immersion testing is recommended if requires other specific data) |

|

Anticorrosion waterproof protection of demineralized water tanks, storage tanks, towers and other facilities in power plant industry.

5.Package:

Two-component, A component 220KG / 200L barrel, B component 210KG / 200L barrel.

6.Storage/Shelf Life:

Ideal storage condition is 5-35 ℃ in cool and dry place, avoid direct sunlight. / Nine months

CATEGORIES

KNOWLEDGE

CONTACT US

Name: Lily Lu

Mobile:86-13922763266

Tel:86-20-38993165

Whatsapp:8613922763266

Email:lilylu@huisins.com

Add:Room 206,Building 21,LongTeng Xing Cheng,No.68 LongTeng South Road, DongXiao Town, XinLuo District,LongYan City,FuJian Province.China