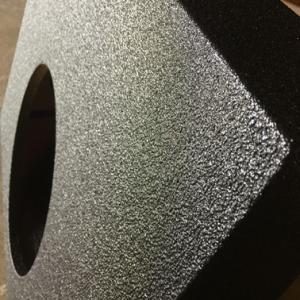

Single-Component Polyurea Waterproof Anticorrosion Protective Coating

- Product Item : ST800B

- Category: Hand-Applied Polyurea Coatings

- ST800B is a single-component aromatic polyurea coating designed for high-performance waterproofing and anti-corrosion protection. It demonstrates excellent adhesion to various substrates and, owing to its unique chemical structure, provides not only outstanding resistance to corrosive chemicals but also superior physical properties such as high elasticity, tensile strength, abrasion resistance, impact resistance, and scratch resistance.

1. Description

ST800B is a single-component aromatic polyurea waterproof and anti-corrosion coating material. It exhibits excellent adhesion to a variety of substrates. Thanks to its unique chemical structure, the product offers not only outstanding resistance to chemical corrosive media, but also possesses superior physical properties including high elasticity, strength, abrasion resistance, impact resistance, and scratch resistance.

2. Features

l High solids, low VOC emissions

l Easy to apply, brush, roller, air spray or airless spray all suitable.

l High physical properties of wearable, impact resistance and scratch resistance

l Excellent waterproof performance

l Excellent chemical resistance, can withstand certain concentration of acid, alkali, salt, oil, organic solvents etc.

l Excellent adhesion force, fast bonding well on the surface of steel, concrete, wood, fiberglass and other substrates.

l Wide temperature requirements, can be used in environment of -50 ℃ ~ 120℃.

l One component material, easy operation without ratio mixed, reducing labor costs

Application Scope

Anticorrosion waterproof protection of petroleum, chemical, transportation, construction, electricity, container and other industries. Maintenance of bridges, waterproof anticorrosion of tunnels, waterproofing protection of industrial floor, sewage water treatment pool, building roofing, water conservancy dam, hydropower station buildings.

3. Products information

|

Item |

Results |

|

Appearance |

Color is adjustable |

|

Specific gravity |

1.2 |

|

Viscosity (cps )@20℃ |

420 |

|

Solid content (%) |

75(vary with different colors) |

|

Tack-Free Time (hrs) |

1.5-2 |

|

Pot life (hrs) |

1 |

|

theoretical coverage |

0.15kg/m²(thickness 100um) |

4.Physical properties

|

Item |

Test standard |

Result |

|

Hardness (Shore A) |

ASTM D-2240 |

82 |

|

Elongation at Break(%) |

ASTM D-412 |

400 |

|

Tensile strength(Mpa) |

ASTM D-412 |

24 |

|

Tear strength (KN/m) |

ASTM D-624 |

65 |

|

Abrasion resistance (750G/500r)/mg |

HG/T 3831-2006 |

10 |

|

Adhesive strength(Mpa)concrete base |

HG/T 3831-2006 |

3.2 |

|

Adhesive strength(Mpa) steel base |

HG/T 3831-2006 |

10 |

|

Impact Resistance (kg.m) |

GB/T23446-2009 |

1.0 |

|

Density(g/cm³) |

GB/T 6750-2007 |

1.2 |

5.Chemical resistance

|

Acid resistance 10% H2SO4 or 10%HCI,30d |

No rust, no bubbles, no peel off |

|

Alkali resistance 30% NaOH, 30d |

No rust, no bubbles, no peel off |

|

Salt resistance 30g/L,30d |

No rust, no bubbles, no peel off |

|

Salt spray resistance, 2000h |

No rust, no bubbles, no peel off |

|

Oil resistance 0# diesel, crude oil, 30d |

No rust, no bubbles, no peel off

|

6.Application environment

Environment temperature

-5℃-35℃

Relative humidity

35-85%

Dew point

When applying on the surface of metal materials, the temperature must be at least 3℃ above the dew point.

7. Application tips

Recommended dft: 100-200 (as design requirement)

Re-coating interval: 4-24h, if the interval time exceed 24h or has dust deposited, sand-blasting first and clean well prior to application.

Coating method: airless spray, air spray, brush, roller.

8.Shelf Life

storage temperature: 5℃~32℃

shelf life: 10 months (sealed)

store in cool and ventilated place, avoid direct sunshine, keep away from heat

package: 5kg/bucket, 20kg/bucket, 25kg/bucket.

CATEGORIES

KNOWLEDGE

CONTACT US

Name: Lily Lu

Mobile:86-13922763266

Tel:86-20-38993165

Whatsapp:8613922763266

Email:lilylu@huisins.com

Add:Room 206,Building 21,LongTeng Xing Cheng,No.68 LongTeng South Road, DongXiao Town, XinLuo District,LongYan City,FuJian Province.China