Special Pure Polyurea For Drinking Water

- Product Item : PS500C

- Category: Spray Polyurea Coatings

- PS500C is a safe and environmentally friendly anti-corrosion coating for potable water facilities, formed by the reaction of isocyanate and amino compounds. It complies with strict national potable water standards (Health Permit License No. 3200-0005) and is certified by SGS to meet U.S. FDA 21 CFR 175.300 regulations for food-contact coatings.

Description

PS500C is a safe and environmentally friendly potable water anticorrosion coating, formed by the reaction of isocyanate and amino compounds. It complies with strict national potable water standards (Health Permit License No. 3200-0005) and is verified by SGS to meet FDA 21 CFR 175.300 for food-contact coatings.

PS500C offers high reactivity and rapid curing, allowing for seamless application on complex surfaces without sagging. It forms a dense, impermeable barrier that effectively resists corrosion, water penetration, abrasion, impact, and aging. With adjustable hardness, it can be tailored to provide either high elasticity or high strength, making it suitable for a wide range of industrial and protective applications.

Product features

* Compliant with FDA 21 CFR 175.300 for food-contact coatings, verified by SGS.

* Solvent free, 100% solids, safe, environmentally friendly, odor free.

* Rapid cure, can be sprayed forming on any bent, slope and vertical surfaces without sagging.

* Dense coating seamless, good flexibility.

* High adhesive strength, fast bonding well on steel, concrete, wood, glass fibers and other substrates

* Excellent impact resistance, abrasion resistance

* Excellent corrosion resistance and chemical resistance properties, such as acids, alkalis, salts, etc.

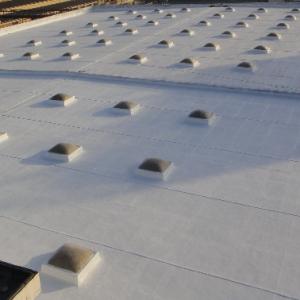

* Excellent waterproof performance

* Good shock absorption performance

Product Applications

Water pipes, water purification pipelines, water tanks, water pools, water storage tanks and other areas of drinking water sanitation standards of anti-corrosion waterproof projects

Products information

|

Item |

Part A |

Part B |

|

Appearance |

Pale yellow liquid |

Adjustable color |

|

Specific gravity |

1.08 |

1.02 |

|

Viscosity(cps)@25℃ |

820 |

670 |

|

Solid content (%) |

100 |

100 |

|

Mixing ratio(volume ratio) |

1 |

1 |

|

Gel time(second)@25℃ |

4-6 |

|

|

Tack-Free Time(second) |

10-20 |

|

|

Theoretical Coverage (dft) |

1.08kg/㎡ film thickness:1mm |

|

Physical properties

|

Item |

Test standard |

Result |

|

Elongation at Break (%) |

ASTM D-412 |

472 |

|

Tensile strength (Mpa) |

ASTM D-412 |

17.8 |

|

Tear strength (kN/m) |

ASTM D-624 |

80.6 |

|

Impermeability (0.3Mpa/30min) |

HG/T 3831-2006 |

Impermeable |

|

Wear resistance (750g/500r) /mg |

HG/T 3831-2006 |

5 |

|

Adhesive strength(Mpa)concrete base |

HG/T 3831-2006 |

3.2 |

|

Adhesive strength(Mpa) steel base |

HG/T 3831-2006 |

11.5 |

|

Density(g/cm³) |

GB/T 6750-2007 |

1.01 |

|

Cathodic disbondment [1.5v,(65±5)℃,48h] |

HG/T 3831-2006 |

≤15mm |

Physical properties

|

Acid resistance 10% H₂SO₄or 10%HCI,30d |

No rust, no bubbles, no peel off |

|

Alkali resistance 10% NaOH, 30d |

No rust, no bubbles, no peel off |

|

Salt resistance 30g/L,30d |

No rust, no bubbles, no peel off |

|

Salt spray resistance, 1000h |

No rust, no bubbles, no peel off |

|

Oil resistance 0# diesel, crude,30d |

No rust, no bubbles, no peel off |

|

Hygienic performance |

conforms to the regulation for the evaluation of protective materials for drinking water, issued by Sanitary license approval [2001]161 |

|

(For reference: the above data is acquired based on GB / T9274-1988 test standard. Pay attention to the influence of ventilation, splash and spillage. Independent immersion testing is recommended if requires other specific data) |

|

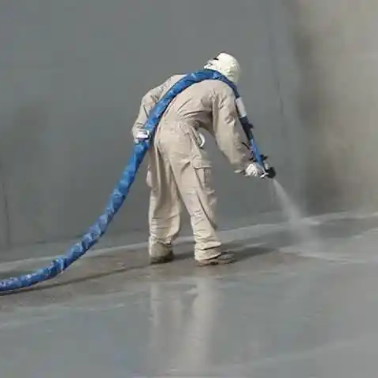

4.Construction method

1) Spray equipment:spray polyurea materials must be constructed using a dedicated (1:1) two-component spray equipment. Such as Graco's H-XP3 and so on.

2) Construction environment requirements: In order to achieve the best coating effect, the site requires ventilation, the ambient temperature should not be lower than 10 °C, the substrate temperature is higher than the dew point of 5 °C, and the air humidity is less than 80%.

3) Surface treatment of the substrate:

a. Leveling the cement surface: leveling the substrate with cement mortar.

b. Grinding of the substrate: the substrate requires fine pitting (to be flat), the surface of the substrate is polished, the scar and the floating slurry are removed, and the position of the negative angle of the yin angle is treated with emphasis, and the yin angle is straight and yang. The corner suggests eight-point angle processing.

c. Cleaning: The dirt on the surface of the substrate cleaned with oil-free, water-free compressed air will clean up the debris that affects the construction of polyurea.

4) Brush primer: brush the concrete special primer, evenly brushed, no leakage coating, no defects.

5) Scrape putty: Apply putty to seal the trachoma and micropores on the concrete surface.

6) Spray polyurea: Spray with special polyurea spraying equipment and polyurea spray gun. Use cross method to repair leak spray and reduce stress.

7) Spraying polyaspartic polyurea topcoat: Spraying with special polyurea spraying equipment and polyurea spray gun, spraying evenly without defects and leaking spray.

5.Package

Two-component, A component 220KG / 200L barrel, B component 210KG / 200L barrel.

6.Color

Spray polyurea material standard color is White, can also provide other colors according to user requirements

7.Storage/Shelf Life

Ideal storage condition is 5-35 ℃ in cool and dry place, avoid direct sunlight. / Nine months

CATEGORIES

KNOWLEDGE

CONTACT US

Name: Lily Lu

Mobile:86-13922763266

Tel:86-20-38993165

Whatsapp:8613922763266

Email:lilylu@huisins.com

Add:Room 206,Building 21,LongTeng Xing Cheng,No.68 LongTeng South Road, DongXiao Town, XinLuo District,LongYan City,FuJian Province.China