Single-Component Aliphatic Polyurea Waterproof And Anti-corrosion Protective Coating

- Product Item : ST800F

- Category: Hand-Applied Polyurea Coatings

- A high-performance, single-component coating offering exceptional UV stability, waterproofing, and corrosion resistance. Designed for long-term outdoor use, it retains color without chalking or discoloration. Provides strong adhesion, durability, and a decorative finish across diverse substrates. Easy to apply, ideal for industrial and infrastructure protection.

1. Description

ST800F is a single component aliphatic polyurea waterproof anti-corrosion coating material, which has excellent adhesion to various substrates. Due to the unique chemical structure of aliphatic prepolymers, this product not only has excellent high elasticity, high strength, wear resistance, and impact resistance, but also has excellent corrosion and weather resistance. It does not pulverize or change color when used outdoors for a long time, and has good decorative effects.

2. Features

· High solid content, low VOC emissions

· Simple application: brush, roller, or spray

· Outstanding wear and impact resistance

· Superior waterproofing performance

· Excellent resistance to acids, alkalis, salts, oils, and solvents

· UV resistant; will not powder or discolor outdoors

· Strong adhesion to steel, concrete, wood, and fiberglass

· Wide application temperature: -50℃ to 80℃

· Single-component; no mixing required, easy to use

Application Scope

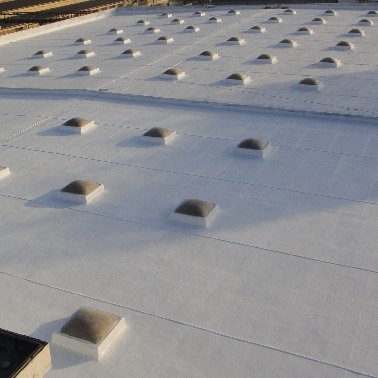

Outdoor waterproof and anti-corrosion protection for industries such as petroleum, chemical, transportation, construction, power, and containers. Such as bridge maintenance, building roof waterproofing, water conservancy dams, hydropower station building waterproofing, etc.

3. Products information

Item

Results

Appearance

Color adjustable

Specific gravity

1.2

Viscosity (cps )@20℃

500

Solid content (%)

75 (vary with different colors)

Tack Free Time (hrs)

3-5

Pot life(hrs)

1

Theoretical Coverage

0.16kg/m2 (thickness 100um)

4. Physical properties

|

Item |

Test standard |

Result |

|

Hardness (Shore A) |

ASTM D-2240 |

82 |

|

Elongation at Break (%) |

ASTM D-412 |

350 |

|

Tensile strength(Mpa) |

ASTM D-412 |

22 |

|

Tear strength (kN/m) |

ASTM D-624 |

63 |

|

Wear resistance (750g/500r)/mg |

HG/T 3831-2006 |

8 |

|

Adhesive strength (Mpa), metal base |

HG/T 3831-2006 |

10 |

|

Adhesive strength (Mpa), concrete base |

HG/T 3831-2006 |

3.5 |

|

Impact resistance(kg.m) |

GB/T23446-2009 |

1.0 |

|

Density(g/cm³) |

GB/T 6750-2007 |

1.2 |

|

Anti-aging, accelerated aging 1000h |

GB/T1865-2009 |

No bubbles, no cracking, no rust or peeling; Powder level 0, color change level 2, loss of light level 2 |

5.Chemical resistance

|

Acid resistance 10% H2SO4 or 10%HCI,30d

|

No rust, no bubbles, no peel off |

|

Alkali resistance 30% NaOH, 30d |

No rust, no bubbles, no peel off |

|

Salt resistance 30g/L,30d |

No rust, no bubbles, no peel off |

|

Salt spray resistance, 2000h |

No rust, no bubbles, no peel off |

|

Oil resistance 0# diesel, crude oil, 30d |

No rust, no bubbles, no peel off

|

6. Application environment

|

Environment temperature |

-5℃-35℃ |

|

Relative humidity |

35-85% |

|

Dew point |

When applying on the surface of metal materials, the temperature must be at least 3℃ above the dew point. |

7. Application tips

Recommended dft: 100-200um (or according to design requirements)

Re-coating interval: 6-30h. If the coating time exceeds 30 hours or there is dust accumulation on the surface, it is recommended to use sandpaper to polish and clean before application.

Recommended coating methods: airless spraying, air spraying, brush, roller

Substrate treatment

Metal surface: It is recommended to sandblast to achieve Sa2.5 level according to ISO8501-1 or GB8923 standards.

Concrete surface: achieve a strong, dense, flat, clean, and dry state. There should be no phenomena such as sanding, shelling, cracks and honeycomb. Usually, putty is needed for repair.

Wood surface: clean, dry, without burrs, fragments, and loose debris.

The application treatment of other substrates please consulted with HUISINS technical personnel.

Application note

This product can be used at low temperatures below -10 ℃. When using in low-temperature environments, it is recommended to place the paint bucket in an air-conditioned room for at least 24 hours.HUISINS recommends mixing the paint evenly before use, pour out the accurate quantity of material that will use up in one time and seal well immediately. Don’t pour the rest liquid to the original bucket.The viscosity of the coating has been adjusted as needed when this product leaves the factory. thinner shall not be random added by the applicators. Call the manufacturer for the instructions of special thinner if the viscosity changed as the application environment and humidity.

8.Curing time

|

Substrate temperature |

Surface dry time |

Foot traffic |

Solid dry |

|

+10℃ |

6h |

30h |

7d |

|

+20℃ |

4h |

24h |

6d |

|

+30℃ |

3h |

20h |

5d |

9.Shelf Life

storage temperature: 5℃~35℃

shelf life: 10 months (sealed)

store in cool and ventilated place, avoid direct sunshine, keep away from heat

package: 5kg/bucket, 25kg/bucket

CATEGORIES

KNOWLEDGE

CONTACT US

Name: Lily Lu

Mobile:86-13922763266

Tel:86-20-38993165

Whatsapp:8613922763266

Email:lilylu@huisins.com

Add:Room 206,Building 21,LongTeng Xing Cheng,No.68 LongTeng South Road, DongXiao Town, XinLuo District,LongYan City,FuJian Province.China